|

|

Manufacturing Capability

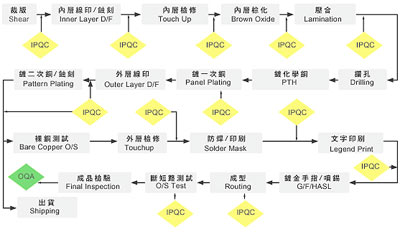

In-Process Control Chart

Outgoing Quality Assurance Case Timetable

PCB

We keep holding a consistent

persistence of specialty and design on work of PCB manufacturing, not

because of CAST consideration, but of board production, basic system

regulation requirements and quality. With the option to cooperate with

the board manufacturer to come up with the best solution for cost and

quality.

Manufacturing Capability

Technology

Description

Now

Under

Development

Minimum

Trace/Space (inner/outer)

5/5 mils

4/4 mils

Minimum

Finished Hole Diameter

10 mils

6 mils

Maximum

Aspect Ratio

8:1

10:1

Minimum

Board Thickness - 4 Layer

16 mils

12 mils

Minimum

Board Thickness - 6 Layer

24 mils

22 mils

Maximum

Board Thickness

125 mils

125 mils

Minimum/Maximum

Layer

2/16

up to 20

Minimum

SMT Device Pitch

12 mils

10 mils

Minimum

SMT Device Land Width

8 mils

6 mils

Board

Flatness Tolerance

±0.7%

±0.5%

Layer to

Layer Reg. Tolerance

±5 mils

±4 mils

Impedance

Control

Partial

Full

Entek /

Gold Plating

Yes

Yes

Board

Size

20" *

20"

24"

* 24"

In-Process Control Chart

Outgoing Quality Assurance

Case Timetable Classification/Layer |

|

ADD: 10F.-2, No.192, Sec. 2, Zhongxing Rd., Xindian Dist., New Taipei City 23146, Taiwan (R.O.C.) TEL: 886-2-29113596 ext 100 All right reserved by Mouse-Team |